Module Washing Solutions

Clean Modules, Clear Profit

Improve asset production by 12+ percent with Cypress Creek’s owner-driven module washing program.

What We Deliver

Neglected pollen, dust, and industrial particulates can erode more than 15% of generation. Our nationwide crews pair data rich soiling diagnostics with high-capacity, water-smart washing systems that reclaim lost production, lengthen module life, and can pay for themselves in as little as two months. More than 4GW of panels cleaned to date have averaged a 6% uplift—and individual sites have seen gains of more than 12%.

Why Cypress Creek Solutions?

Soiling creates a film on panels, reducing efficiency and production. A recent study from the National Renewable Energy Laboratory states that revenue losses due to soiling can easily reach millions of dollars per year.

Owner’s Mindset = Bankable Results

We wash our own more than 2GW IPP fleet, so every recommendation is grounded in hard ROI, not extra truck rolls.

Science-Backed Targeting

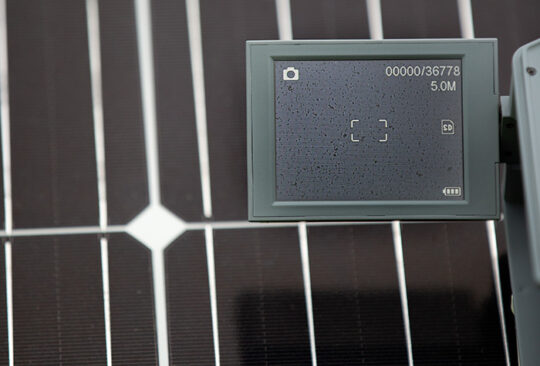

Aerial thermography, proprietary microscopy, and an analytics platform pinpoint sites where washing will create the biggest revenue bump.

High-Throughput, Low-Water Tech

Mobile rigs clean ~10MW per team, per day while minimizing water use and labor hours.

Safety & Compliance First

OSHA-trained crews operate purpose-built equipment that protects modules, personnel, and the environment.

Transparent Performance Reporting

Pre/post-wash data, uplift confirmation, and payback calculations are possible for every wash.

Owner’s Mindset = Bankable Results

Owner’s Mindset = Bankable Results

We wash our own more than 2GW IPP fleet, so every recommendation is grounded in hard ROI, not extra truck rolls.

Science-Backed Targeting

Science-Backed Targeting

Aerial thermography, proprietary microscopy, and an analytics platform pinpoint sites where washing will create the biggest revenue bump.

High-Throughput, Low-Water Tech

High-Throughput, Low-Water Tech

Mobile rigs clean ~10MW per team, per day while minimizing water use and labor hours.

Safety & Compliance First

Safety & Compliance First

OSHA-trained crews operate purpose-built equipment that protects modules, personnel, and the environment.

Transparent Performance Reporting

Transparent Performance Reporting

Pre/post-wash data, uplift confirmation, and payback calculations are possible for every wash.

How We Work

Assessment

Portfolio or site-level review of production data, weather-adjusted KPIs, and inverter history identify the most lucrative wash candidates.

Root-Cause Analysis

On-site inspections, drone imagery, and cell-level microscopy quantify soiling loss and forecast uplift.

Mobilization & Cleaning

Water-efficient, research-driven equipment and skilled technicians wash up to 10MW/day, even on challenging layouts.

Evaluation & Reporting

Post-wash regression analysis verifies kWh gains, calculates payback, and refines future cleaning schedules.

Frequently Asked Questions

How much extra energy can I expect?

Portfolio averages hover around 6%, with single-site gains recorded over 12%, depending on soil type and severity.

What drives the payback period?

Soiling severity, PPA rate, and cleaning cost. Historic projects recoup costs in 2–10 months.

How do you decide when to wash?

We combine production analytics, rain/soiling models, and microscopy data to trigger washes only when ROI is positive.

Will washing void my module warranty?

No. We follow manufacturer guidance and use soft-bristle, low-pressure systems approved for utility-scale modules.

Where does the water come from—and how much?

Mobile rigs carry or tap on-site sources; optimized nozzles and chemistry cut usage well below traditional methods.

Can the plant stay online during cleaning?

Yes. Our crews coordinate with the control center or local team to maintain safety and production continuity. Night washing is also available.